ED SERIES (5 MODELS)

The ED series are fully electric servo bending machines, driven by a servo motor, which makes its manufacturing efficiency much better than the conventional hydraulic press brake. In addition, no hydraulic oil is required, which is environmentally friendly.

Compared with the conventional equipment, fully electric servo bending machines can save up to ~80% of energy and it features fast slider speed, high production efficiency and bending precision, and can have the deviation of the bending angle well controlled within ±0.5mm.

Length of workbench from 800mm to 2500mm

Tonnage from 25 Ton to 80 Ton

Opening of 420mm

Throat depth of 400mm

DUAL SERVO SERIES (28 MODELS)

The HYD series adopts a new type of integral or split mainframe structure with strong rigidity and high toughness. The latest oil‐electric hybrid drive system has the advantages of energy saving and consumption reduction, high efficiency and low heat. At the same time, it greatly reduces working noise, improves work efficiency, and ensures the stability of the machine. It has a modern and novel industrial appearance design.

Length of workbench from 2500mm to 6000mm

Tonnage from 80 Ton to 400 Ton

Opening of 450mm to 600mm

Throat depth of 400mm & 450mm

DOWN ACTING HYBRID SERIES (30 MODELS)

The HY series are down-acting hybrid CNC machines, with a fully steel welded structure with good rigidity and stability. The machines are equipped with a Swiss CybTouch 12PS control system, and the servo motor is used as the main power source of the hydraulic pump. An efficient and reliable rear-gauge system together with an automatic deflection compensation workbench is used, suitable for handling large and thick parts.

Length of workbench from 400mm to 6000mm

Tonnage from 50 Ton to 400 Ton

Opening of 450mm to 600mm

Throat depth of 300mm to 450mm

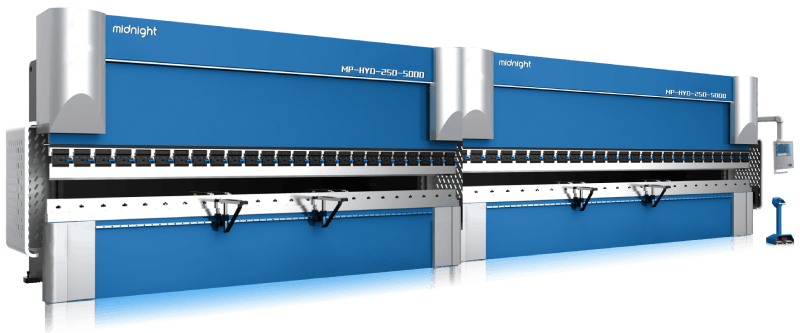

DUAL LINKAGE MACHINE

The HYD series adopts the same specification of a double‐cylinder host, equipped with a dual‐machine linkage synchronous device. A double‐machine linkage bending machine can process special work‐pieces, especially for urban construction, automotive manufacturing, highway street lamp poles, power poles, and other special work‐piece processing and manufacturing. Two machines can be used alone or in double‐machine linkage. An optional workbench with liquid compensation eliminates the compensation on both sides of the bend and the deflection deformation on both sides of the bending.

Length of workbench 6400mm

Tonnage 640 Ton

Opening 600mm

Throat depth o 400mm

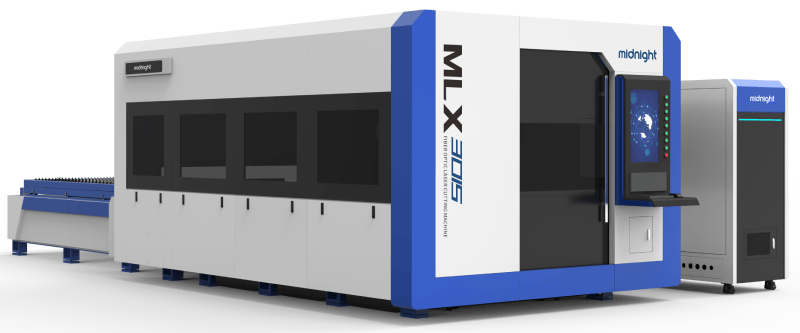

MLX SERIES

Designed for high‐performance cutting, the MLX Series is a fully enclosed, high‐power series that is equipped with lasers up to 30 kW. Combining a unique heavy‐duty frame, dynamic pallet changer design, advanced controls and multi‐function cutting head, it ensures continuous productivity at the highest levels.

Bed sizes of 1500mm x 3000mm; 2000mm x 4000mm and 2500mm x 6000mm.

Laser power from 3kW to 30kW

MHLS SERIES (2 MODELS)

Combining the power of sheet metal laser cutting with the ability to process tubes and profiles, the MHL series offers unmatched flexibility to cover a wide range of sizes, industries and applications.

Bed sizes from 1500mm x 3000mm and 2000mm x 4000mm

Laser power from 3kW to 20kW

Tube length 6m

Tube diameter 10mm to 220mm

Square 20mm to 155mm

MLG SERIES (2 MODELS)

Segmented design

The modular design facilitates the transportation and assembly of the bed, saving transportation costs, as

well as future maintenance of individual parts and modules.

Split cutting table

Split‐style to prevent the heat generated by cutting from being conducted to the bed frame, which could cause deformation. It also allows for easier replacement of tables.

Low height machine body

The low height bed design makes it easy to load and unload materials.

3D Bevel cutting

Supports visual mode calibration solutions, convenient and fast. Offers bevel cutting compensation when the

cutting plate is placed unevenly. Supports two corner motion methods: “Direct Transition” and “Corner Normal Vector Optimisation”.

Supports tilted piercing

Supports arc jump (frog leap) cutting ways in both straight cutting and bevel cutting. Supports piercing slag

removal, vibration suppression, and micro‐joint.

Bed sizes — 13m x 3m (2 plates of 6.5m x 3m) / 26m x 3m (2 plates of 13m x 3m)

Laser power from 20kW to 60kW

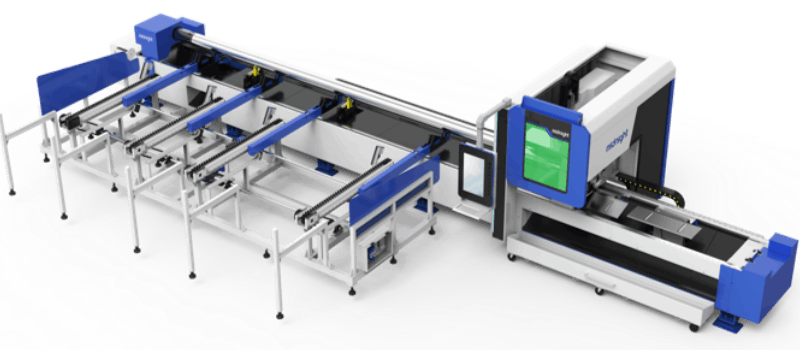

2D & 3D PROFILE AND SECTION CUTTING

With the power to process Profiles and Sections up to 700mm in size, 2D and 3D Bevel Cutting, and loading systems for every type of application, the MTL Series is unmatched in performance and flexibility.

220 – 560mm and 220 – 320mm Sections and Profiles.

Heavy Duty Design with 2D and 3D Bevel Cutting.

Lengths up to 12m in both Input and Output.

Different Loader Options for Profiles, Sections, and Tubing for full automation.

Laser power from 1.5kW to 12 kW.

Designed for a wide range of Welding, Cutting and Cleaning applications the MLW series is a must have at every fabrication shop. With a quick setup design, powerful water‐cooling system and powers up to 3kW, the MLW series offers high productivity in different materials and up to 6mm in thickness.

Laser power from 1.5kW to 3.0kW

Laser Welding

New generation welding technology enables you fast, better and easier welding.

Laser Cleaning

Laser cleaning can be used as a professional cleaning tool and a pipe welding

pre‐treatment process.

Laser Cutting

For thin material and no high requirement of cutting effect, the extra function is very

useful.