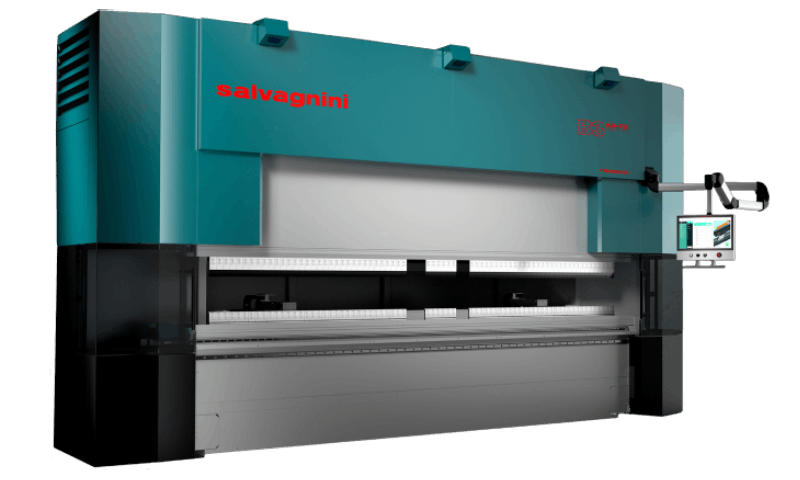

THE IDEAL PRESS BRAKE FOR DYNAMIC PRODUCTION

The B3 was designed by combining the features and benefits of electric and hydraulic press brakes with Salvagnini's in‐depth knowledge of automation, software, mechanics, and electronics.

Whatever the level of automation chosen from the four available (ATA, ATA.L, MVM, AU‐TO), the B3 remains the solution with the smallest footprint available on the market.

Is available in a wide range of sizes, from 2000mm to 6000mm, and from 80 to 400 tons.

Thanks to the MAC3.0 technology, it guarantees bending repeatability and precision.

Reduces power consumption while maintaining high levels of productivity with the Salvagnini Power Unit.

Allows kit and batch‐one production and efficient bending of parametric parts, thanks to ATA and AU‐TO automation.

S1 PUNCH LASER‐COMBI MACHINE

The S1 integrates the punching and cutting operations and automatically manages repositioning and separation. With the patented multi‐press head, the tools are always available for nesting and multiple jobs, with no re‐tooling in‐cycle or manual intervention. Thanks to the controlled stroke of the tools, it extends the range of machines available, including offset, ribbing and tapping. Can be integrated with entire Salvagnini automation range. Sheet size of 1500 x 4000 and a laser source of 2.0 & 3.0kW.

S4 PUNCHING-SHEARING CENTER

The S4 natively integrates the punching and separation operations and automatically manages the feeding, sorting and unloading cycles which, when possible, are performed in masked time. With the patented multi‐press head, the tools are always available for nesting and multiple jobs, with no re‐tooling in‐cycle or manual intervention. The proprietary Punch & Cut algorithm optimizes the integrated shearing cuts for separating the single parts in the sheet in a fast, flexible and automatic sequence with no waiting times for unloading the part. Sheet size of 1600 x 4000.

S4.G4 ADVANCED HYBRID TECHNOLOGY PUCHING AND SHEARING CENTER

The S4.G4 punching‐shearing machine is the ideal solution for businesses looking for productivity, flexibility, reactivity and efficiency. The S4.G4 performs all the part punching, forming and separation operations by subtraction, destroying the skeleton to ensure that the parts flow progressively downstream: this eliminates the need for regripping and rapidly feeds the next production step. Sheet sizes of 1600 x 4000.

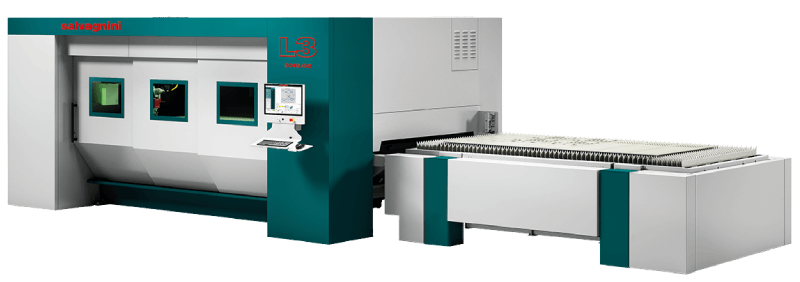

ADAPTIVE FIBER LASER

The L3 is equipped with a single laser head, designed by Salvagnini, used to cut all the allowed materials and thicknesses. It is equipped with the patented DRY‐COOLING system, used to actively control the temperature of the optics. Its process sensors control and adapt the piercing in real time, monitoring any cutting losses, stopping the process, and restarting it with appropriately corrected parameters. The TRADJUST function, integrated into the proprietary control, ensures automatic parameter modulation according to the trajectories, making the system easier to use. Sheet sizes of 1500 x 3000; 1500 x 4000; 2000 x 4000; 2000 x 6000 and fiber source of 2.0kW – 10.0kW.

HIGH PERFORMANCE AND VERSATILE FIBER LASER

L3.G4 is Salvagnini solution for high performance and versatile laser cutting, characterized by an innovative, highly accessible architecture that is unique in the market. Designed to improve ergonomics and simplicity of use and guarantee maximum precision and repeatability of processes, L3.G4 eliminates activities with low added value and optimizes consumption, ensuring lower costs per piece. Sheet size of 1500 x 3000 and fiber source of 2.0kW – 8.0kW

HIGH DYNAMICS FIBER LASER

The L5 is an agile laser: the proprietary functions, the multi‐task human‐machine interface and the artificial vision systems help operators to effortlessly solve the problems in their day‐to‐day work. Salvagnini software solutions effectively connect the laser to the factory ERP and other technologies downstream, guaranteeing the traceability of the parts, supporting the operator in sorting the parts and providing progress feedback in real time to the production manager, whether this is human or virtual. Sheet sizes of 1500 x 3000 and 1500 x 4000. Fiber source of 2.0kW – 10.0kW

ADAPTIVE FIBER LASER

Flexible bending solutions are available in four Ranges P1 – PX – P2.G4 – P4.G4

Can be integrated with different semi-automatic, automatic or robotized feeding devices.

Can handle both kit and batch‐one production thanks to the universal tool that automatically adapts in-cycle.

Automatically adapts to changes in material and the external environment, thanks to MAC 3.0 technology.

Requires operator intervention only for loading and unloading.

A loading/unloading robot can be integrated on the left of the machine using the CI interface.

Can be integrated with different semi-automatic, automatic or robotized feeding devices.

P1 – Maximum bending length of 1250mm and a bending height of 127mm.

PX – Maximum bending length of 2180mm and a bending height of 203mm.

P2 – Available in 5 Models with bending lengths from 1000mm to 2750mm and a bending height of

260mm.

P4 – Available in 8 Models with bending lengths from 2810mm to 4000mm and a bending height of 350mm.

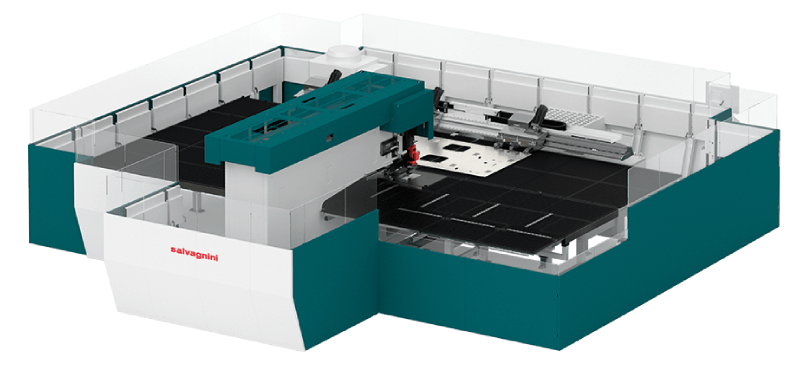

ADAPTIVE, EFFICIENT AND SUSTAINABLE PRODUCTION LINE

S4+P4 Flexible Smart Line (FLS) brings together physical reality – machines and people, and virtual reality – the world of big data, in a single eco‐system which respects people and the environment. FSL analyses and interprets data and acquires useful information for implementing safe and intelligent production flows; it communicates with the external environment and can work in harmony with other functions in the supply chain, reducing scrap, waste and consumption.

Automatically punches, cuts and bends sheet metal without intermediate handling.

Combines productivity and flexibility: the ideal solution for any production strategy, be it kit, single‐batch, or series production. Ensures parametric production and unmanned operation.

Can be integrated with the entire Salvagnini automation range. Works in line or with separate machinery, in full safety.

Reduces energy consumption, using only high‐efficiency components.

STREAM is Salvagnini's answer to the modern industrial context, a programming suite that improves reactivity and reduces costs, operating errors and process inefficiencies.

PARTS is the software used to manage the whole database of products and parts.

VALUES is the software that provides an accurate estimation of production costs.

OPS is the modular production management software. Within the production equation, it acts as the central coordinator, managing and distributing information among all environments and stakeholders involved, eliminating critical points and drastically improving process efficiency.