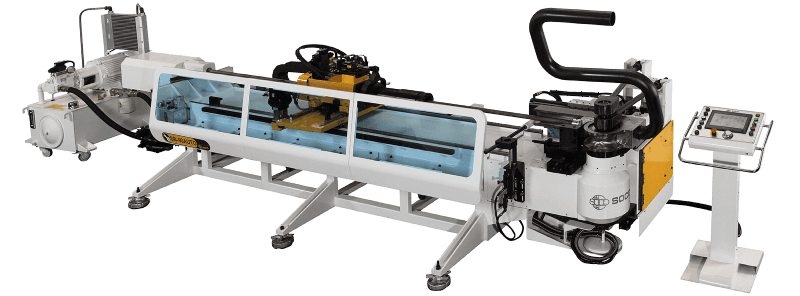

AUTO SERIES (3 MODELS)

The Auto Series CNC Bending Machines are equipped with three programmable axes: feeding electric servo, rotation electric servo, and bending hydraulic (NC). The machine comes with a standard hydraulic assist and is equipped with a wiper, clamping, and pressure die seats. It features programmable early mandrel extraction, a touch screen, motor control, and quick tool change systems.

Maximum tube diameter — Ø 38mm to Ø 90mm

Maximum tube length — 2600mm to 3800mm

Maximum bend radius — Ø 200mm to Ø 250mm

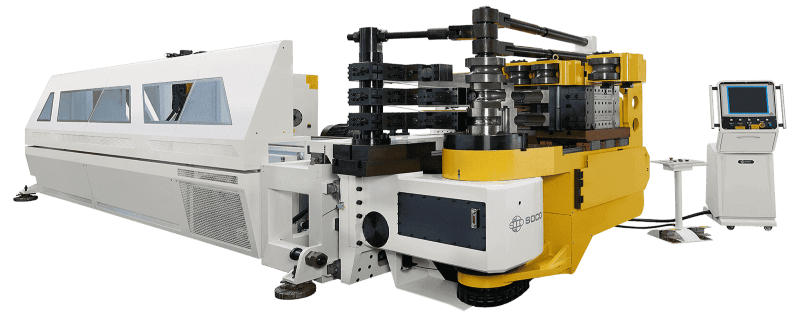

6B SERIES (14 MODELS)

With models that extend up to OD 168 mm capacity, the SOCO CNC 6B series tube bender brings the optimal tube bending power and accuracy solutions to the automotive, trucks, buses, boilers, ship building and other heavy industries.

6B SERIES (14 MODELS)

With models that extend up to OD 168 mm capacity, the SOCO CNC 6B series tube bender brings the optimal tube bending power and accuracy solutions to the automotive, trucks, buses, boilers, ship building and other heavy industries.

V SERIES (18 MODELS)

The V Series CNC Tube Benders combine Draw, Roll and 1D Bending technologies. This combination allows for multiple draw (fixed) and large roll bending radii in a single part, as well as a programmable carriage boost for CLR = 1D Bending. Coupled with either Individual Pressure Die Assists in each draw bending stack or Servo Driven PDA systems, it brings superior performance and flexibility.

Maximum tube diameter — Ø 16mm to Ø 127mm

Maximum tube length — 2070mm to 5700mm

Maximum bend radius — Ø 80mm to Ø 350mm

2B SERIES (8 MODELS)

The 2B series of Tube Benders are fully automatic and cost-effective, with CNC servo-controlled feeding and planning axes to ensure high precision and reliability. Standard accessories include a set of standard mandrels, a hydraulic mandrel extraction system, an auto‐lubricating system for the mandrel, a centralised grease unit for all sliding parts, a pressure die assist system, and a removable push-button operation stand.

Maximum tube diameter — Ø 38mm to Ø 90mm

Maximum tube length — 3000mm to 4100mm

Maximum bend radius — Ø 180mm to Ø 250mm

Maximum square tube — 32mm x 32mm x 3,1t and 51mm x 51mm x 2,5t

LEFT & RIGHT‐HAND SERIES (5 MODELS)

This line combines Draw + Roll + Dual Direction Bending Way technology. It is especially suitable for complex parts and shapes, such as automotive exhaust pipes, healthcare, and fitness equipment.

Maximum tube diameter — Ø 16mm to Ø 51mm

Maximum tube length — 2750mm to 3000mm

Maximum bend radius — Ø 80mm to Ø 180mm

F SERIES — MANUAL OPERATED

PV SERIES — AUTOMATIC AIR CLAMPING VICE

AC SERIES — AUTOMATIC CUTTING AND AIR CLAMPING VICE

Self centering vice with two sides clamping to solidly hold the work piece and ensure a smooth and burr free cutting surface. Low operation noise and low pollution working environment.

Cutting capacity from 80mm to 115mm tube.

Round tube from Ø 80 to Ø 115.

Square tube from 75mm x 75mm to 100mm x 100mm

Rectangular tube from 25mm x 25mm to 100mm x 100mm

AC LINE

Semi‐automatic operation.

Straight and angle cutting.

Air lifting system for angle cut setting.

DR LINE

Fully automatic hydraulic system.

Feeding lengths up to 3 strokes x 1000mm

NC AND NC‐SN LINES

The shortest crop length of any machine in the market.

Vertical slide for maximum cutting power and rigidity.

Maximum tube size Ø 110 to Ø 127

The tube and bar cutting machines incorporate the newest technology with unparalleled functions. This revolutionary innovation brings you the unique loader and unloader — saving 70% labour and material change over time.

Round tube — Ø 10mm to Ø 115mm

Solid round bar — Ø 10mm to Ø 115mm

Solid square bar — 10x10 – 80x80

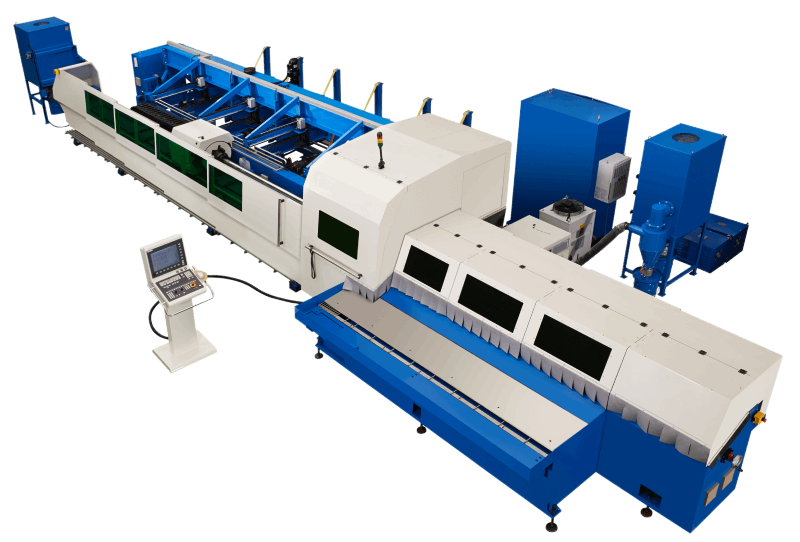

SOCO introduces its newest generation in tube and profile processing technology — the Fiber Laser Cutting System, “SLT‐152‐FIBER”. With over 30 years of experience in the design and manufacturing of tube cutting technology, SOCO specialises in solutions for the tube and pipe industries. The new Fibre Laser Cutting Line is the ultimate solution for integrating multiple machining processes into one system for maximum flexibility, automation and performance.

Cutting capacity Ø 20mm to Ø 152mm

Laser power 1.0kW standard and 2.0kW optional

Straight and bevel cutting

Cutting lengths up to 2000mm or 3000mm (longer on request)

Automatic tube bundle loading

Automatic material alignment

Automatic feeding and rotation